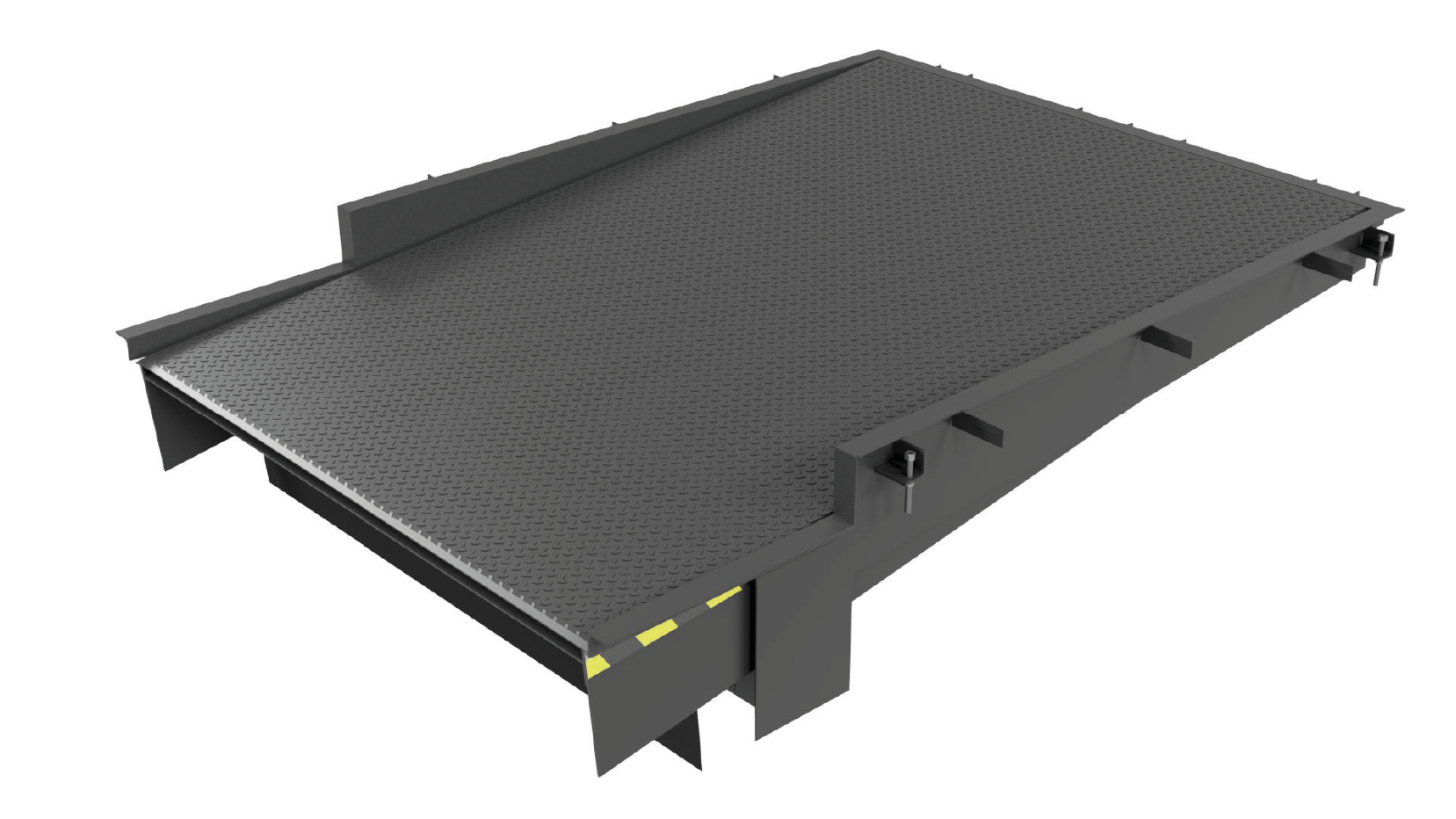

The ESS system is the ideal solution to ensure safety for the docking process as well as for the goods and the driver, who does not have to leave the vehicle directly in front of the dock to open the rear of the trailer. An additional advantage of the system is a significant reduction in costs associated with the loss of energy needed to heat or cool warehouses during loading, since the dooropens after the vehicle is docked and sealed. The AMTRV ESS dock leveller is not only used for internal loading docks, but also for specially developed external loading bays with doors and seals, ideally suited for use in freezer warehouses. When at rest, the platform is lowered to level 0, allowing the doors of the truck to be opened after docking.

- The actuator system consists of a set of cylinders that allows independent extension of the lip

- The lip is extended with a separate actuator

- Separately powered from the hydraulic unit

- Closed hydraulic system

- Stepless adjustment to the vehicle height during loading

- The intuitive AMTRV-ESS control unit with a push buon for auto-return can be combined with a door control unit

The main function of the pan is to connect the leveller with the dock.

The pan is directly filled with concrete.

Available options:

- standard

- RS- Frame before concreting