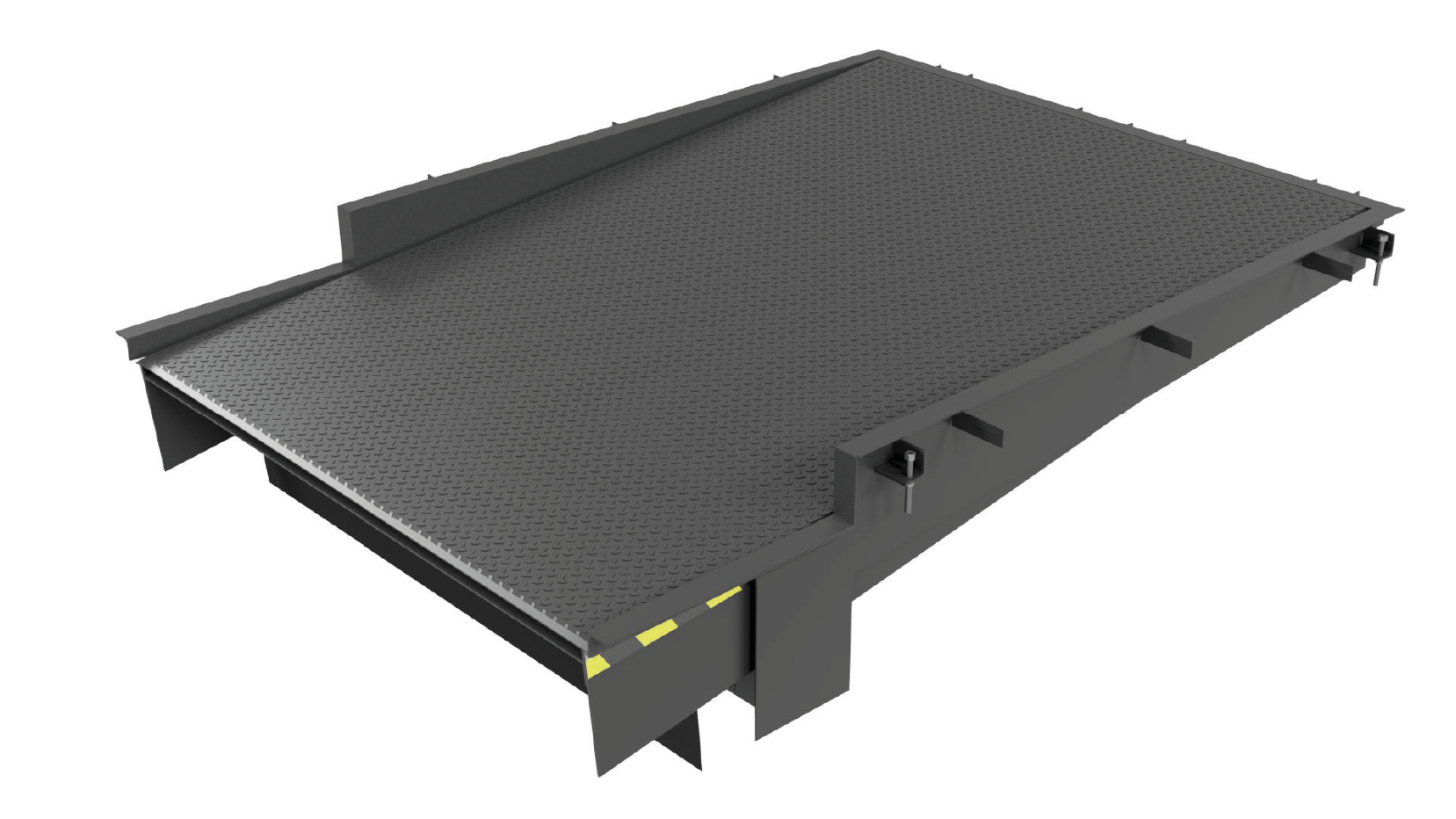

The hydraulic dock leveler serves to bridge the height difference between the building and the vehicle trailer, ensuring a smooth connection. The CD system is equipped with a telescoping, segmented lip, specifically designed to accommodate a wide range of vehicles with varying designs and cargo area dimensions. The operator can select the appropriate vehicle type and platform mode via the control panel. For vans, with narrower loading areas, the telescopic lip is reduced to 1200 mm, with a load capacity of 20 kN. When the full extension is deployed, the platform’s load capacity increases to 60 kN.

- The actuator system consists of a set of cylinders that allows independent extension of the middle section of the lip

- The lip is extended with a separate actuator,separately powered form the hydraulic unit

- Stepless adjustment to vehicle height during loading

- Four - button control TL401

- Intuitive control with the compulsory section of 20 kN or 60 kN operating mode and a button for auto - return

- It is possible to couple the ramp control to the door control

- Control includes protection in the event of a power failure or the use of the emergency switch

- In case of power failure or emergency switch activation, the leveller is protected from descending, stopping and maintaining its current positio

Available options:

- standard

- R-frame

- RS- Frame before conreting

- the drive system consists of a set of cylinders allowing for independent lip central section extension,

- the lip is extended by a separate cylinder, supplied separately from the hydraulic unit,

- closed hydraulic system, • smooth adaptation to the vehicle height during loading.