The telescopic lip dock leveller is designed for picking up pallets with a forklift to load or unload trucks. Its characteristic feature is a telescopic lip guided along bearing rollers. The leveller has the CE mark. Its platform is made of 8/10 mm thick steel checker plate. It is integrated with the service support and connected to the back of the leveller frame with hinges. Fully secure use is ensured by the anti-slip surface, foot protection along the entire length of the platform and the full lifting range of the leveller. Different methods of placing bridges in the foundation are possible.

- the drive system of the leveller is a hydraulic cylinder,

- the lip is lifted by a separate cylinder, powered separately by a hydraulic unit,

- closed hydraulic system (maximum pressure 22 bar),

- smooth adjustment to the vehicle height during loading,

- single-button control,

- protection in the event of a power failure or the use of an emergency switch, the leveller is protected against fall – it will stop and maintain the position it was in at the moment,

- the leveller control system can be coupled with the gate control system.

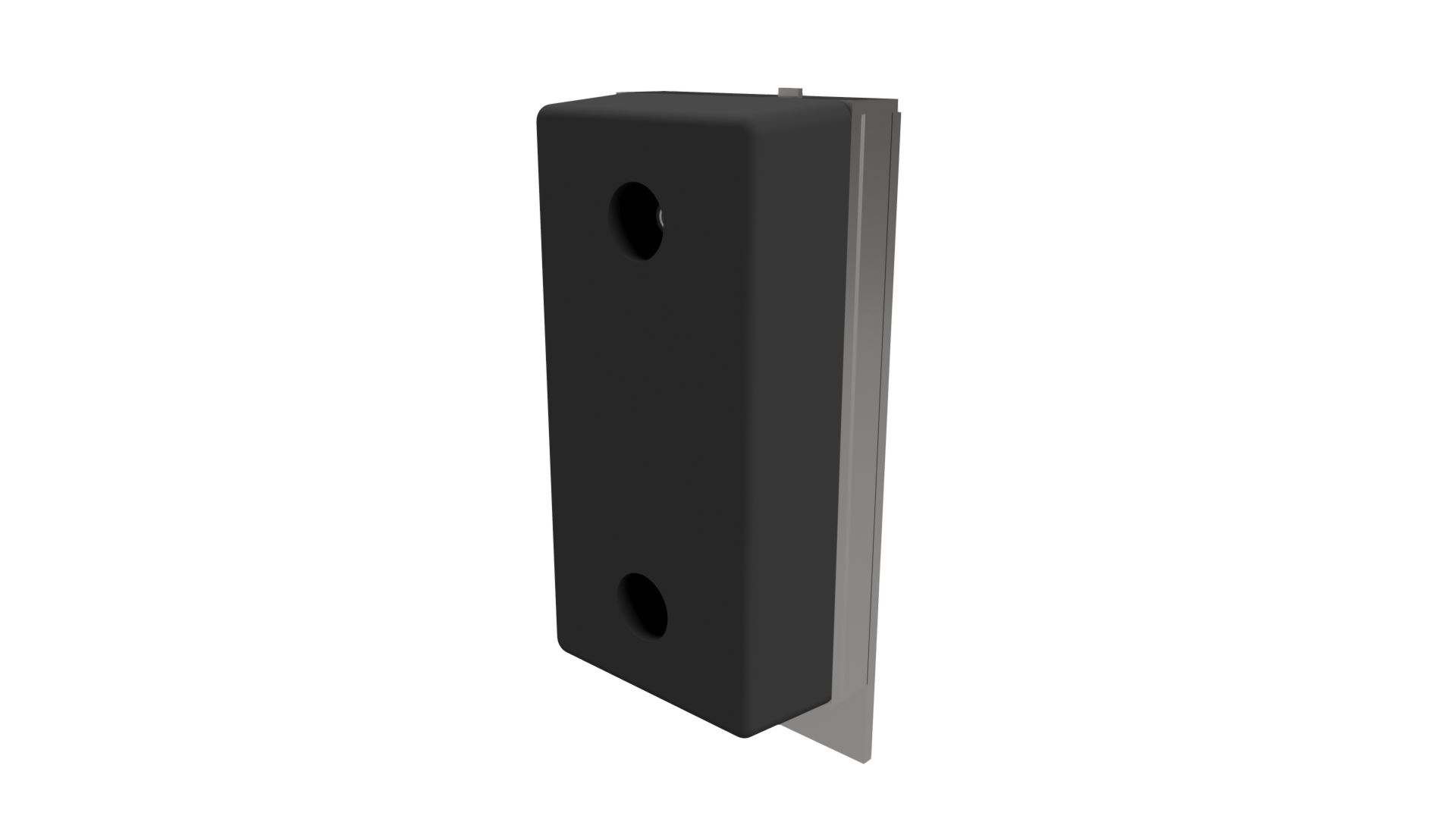

The main function of the pan is to connect the leveller with the dock.

The pan is directly filled with concrete.